Ian Carswell

Ian also has a layout under construction.

Stanier brake van to Diagram 2036 from the Pocket Money Kits

etch. The buffers are from Lanarkshire Model Supplies, type B013,

the correct pattern for this type of van and beautifully cast in

white metal. The springs and axleboxes are a 3D print from Modelu

from my own CAD data.

Stanier brake van to Diagram 2036 from the Pocket Money Kits

etch. The buffers are from Lanarkshire Model Supplies, type B013,

the correct pattern for this type of van and beautifully cast in

white metal. The springs and axleboxes are a 3D print from Modelu

from my own CAD data.

Charles Roberts 14 ton hopper from the Dave Bradwell kit.

Charles Roberts 14 ton hopper from the Dave Bradwell kit.

Hunslet 50t 325hp diesel hydraulic from the Judith Edge kit with a

rake of Hudson side tipping wagons from the RT Models kit. The

Hunslet has a scratch built, compensated chassis and gearbox that

keeps the drive line clear of the cab.

Hunslet 50t 325hp diesel hydraulic from the Judith Edge kit with a

rake of Hudson side tipping wagons from the RT Models kit. The

Hunslet has a scratch built, compensated chassis and gearbox that

keeps the drive line clear of the cab.

Hudson side tipper from the RT Models etched kit. A couple of tricky

bits, and I’m sure the brake mechanism isn’t quite

right, but makes up into a nice model. There’s a couple more

spoil tippers to build. Pretty sure Bachmann won’t be

releasing one of these!

Hudson side tipper from the RT Models etched kit. A couple of tricky

bits, and I’m sure the brake mechanism isn’t quite

right, but makes up into a nice model. There’s a couple more

spoil tippers to build. Pretty sure Bachmann won’t be

releasing one of these!

Night scene at the shed. No 2 stands idle waiting for the morning

shift, illuminated by the light from the shed and the yard lamp.

Night scene at the shed. No 2 stands idle waiting for the morning

shift, illuminated by the light from the shed and the yard lamp.

High Level Barclay built straight out of the box. Easiest kit I ever

built! Steam and smoke courtesy of Photoshop.

High Level Barclay built straight out of the box. Easiest kit I ever

built! Steam and smoke courtesy of Photoshop.

Ubiquitous 1/108 from Airfix kit with Exactoscale FASS suspension

and Masokits brake parts. Midland pattern bufferstops from NS rail

offcuts and plasticard oddments.

Ubiquitous 1/108 from Airfix kit with Exactoscale FASS suspension

and Masokits brake parts. Midland pattern bufferstops from NS rail

offcuts and plasticard oddments.

OBA from the Cambrian kit. Only mods are the fitting of suspension

from Exactoscale FASS system and the odd improvement to the

underframe gubbins. Yes, the prototype was painted just like this

with Railfreight red faded to a sicky pink and a half-baked attempt

to repaint the top planks.

OBA from the Cambrian kit. Only mods are the fitting of suspension

from Exactoscale FASS system and the odd improvement to the

underframe gubbins. Yes, the prototype was painted just like this

with Railfreight red faded to a sicky pink and a half-baked attempt

to repaint the top planks.

A view towards the stopblocks on a short section of siding I built

last year. The stopblocks are made from scribed styrene and BH rail

ends to a Midland Railway drawing reproduced in Midland

Record. Track is C&L . The brick wall is Wills with coping bricks

from plasticard. Foreground foliage is in the style of Norman and

Welch, the bushes and trees in the background are 300mm/ft scale.

A view towards the stopblocks on a short section of siding I built

last year. The stopblocks are made from scribed styrene and BH rail

ends to a Midland Railway drawing reproduced in Midland

Record. Track is C&L . The brick wall is Wills with coping bricks

from plasticard. Foreground foliage is in the style of Norman and

Welch, the bushes and trees in the background are 300mm/ft scale.

Standard BR brakevan built from the etched brass Pocket Money

Kit. Built pretty much as suggested by the instructions. Runs on MJT

compensated W-irons which fit neatly underneath without having to

adjust the ride height (cunning design or pure luck, not sure

which). Verandah corner posts are angle section rather than solid

section due to the fold-up nature of the kit, but it is not

obvious. Something which shows up horribly in the photo are the

rather featureless axlebox castings supplied with the kit, which

would be easy to improve upon with a few lumps of styrene. Good and

cheap introduction to etched brass kits for somebody wishing to dip

the proverbial toe in the flux.

Standard BR brakevan built from the etched brass Pocket Money

Kit. Built pretty much as suggested by the instructions. Runs on MJT

compensated W-irons which fit neatly underneath without having to

adjust the ride height (cunning design or pure luck, not sure

which). Verandah corner posts are angle section rather than solid

section due to the fold-up nature of the kit, but it is not

obvious. Something which shows up horribly in the photo are the

rather featureless axlebox castings supplied with the kit, which

would be easy to improve upon with a few lumps of styrene. Good and

cheap introduction to etched brass kits for somebody wishing to dip

the proverbial toe in the flux.

Some progress on a Bradwell WD. The tender is fully sprung in the

Bradwell fashion. I was sceptical about the merits of 'real'

suspension but watching this tender glide along the track has made a

convert of me. Electrical pick up is from tender one side and loco

on the other. Wheels were shorted by wires on the back of loco

drivers and by silver conductive paint on tender wheels. Works fine.

Hooray, no ******g wipers! Gearbox on back axle of loco is

Exactoscale WGD 36:1. Drive shaft is Ultrascale, but with joints

reduced in diameter to fit in eyewateringly tight space beneath cab

floor and above dragbox. Motor sits on a silicone rubber isolation

mount and structure borne noise from the tender is minimal.

Some progress on a Bradwell WD. The tender is fully sprung in the

Bradwell fashion. I was sceptical about the merits of 'real'

suspension but watching this tender glide along the track has made a

convert of me. Electrical pick up is from tender one side and loco

on the other. Wheels were shorted by wires on the back of loco

drivers and by silver conductive paint on tender wheels. Works fine.

Hooray, no ******g wipers! Gearbox on back axle of loco is

Exactoscale WGD 36:1. Drive shaft is Ultrascale, but with joints

reduced in diameter to fit in eyewateringly tight space beneath cab

floor and above dragbox. Motor sits on a silicone rubber isolation

mount and structure borne noise from the tender is minimal.

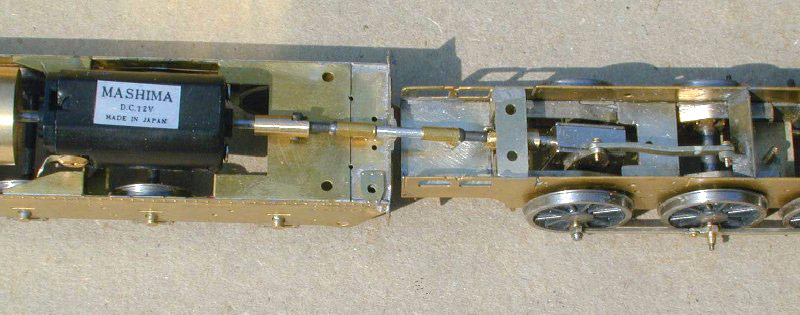

A closer look at the driveline in a Bradwell WD. My first attempt at

a motor in tender configuration. As shown it worked reasonably well

except at very slow speed. Tender chassis was revised to fit a

larger Mashima 1828(?) with the biggest flywheel I can get on the

back. The joint angle on the gearbox input was reduced from the

modest angle you see in the photo to damn near straight by

lengthening the gearbox reaction arm and taking a chunk out of the

top of the dragbox. Works very well indeed now at all speeds, smooth

and silent ( and therefore unprototypical !). So far the parts have

gone together with uncanny accuracy, however Mr Bradwell doesn't get

too specific about drive components so that's where the hard work

is.

A closer look at the driveline in a Bradwell WD. My first attempt at

a motor in tender configuration. As shown it worked reasonably well

except at very slow speed. Tender chassis was revised to fit a

larger Mashima 1828(?) with the biggest flywheel I can get on the

back. The joint angle on the gearbox input was reduced from the

modest angle you see in the photo to damn near straight by

lengthening the gearbox reaction arm and taking a chunk out of the

top of the dragbox. Works very well indeed now at all speeds, smooth

and silent ( and therefore unprototypical !). So far the parts have

gone together with uncanny accuracy, however Mr Bradwell doesn't get

too specific about drive components so that's where the hard work

is.