Having joined the society eighteen months ago (whoops, how did that time pass?), the advert for the workbench seemed like a good way to get this years modelling started.

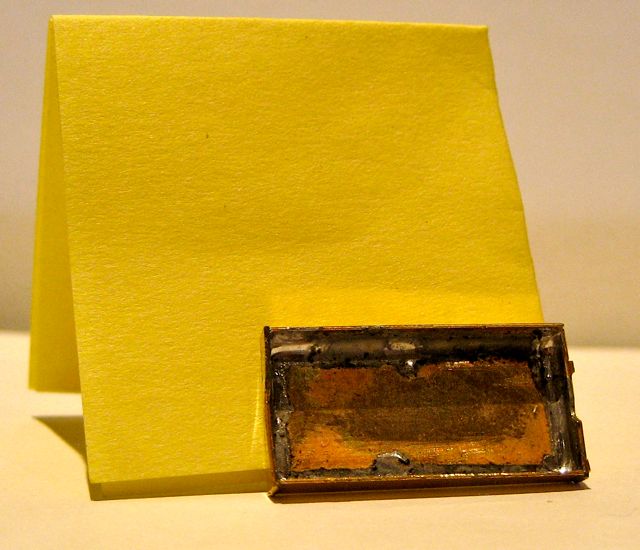

We got stuck right in with some soldering, and after a demonstration, I put together my first bit of structural soldering:

For scale, the long side measures around 25mm.

We did some more soldering to start construction of a compensation unit (more later...), and then had a go at using low temperature solder to attach whitemetal to brass:

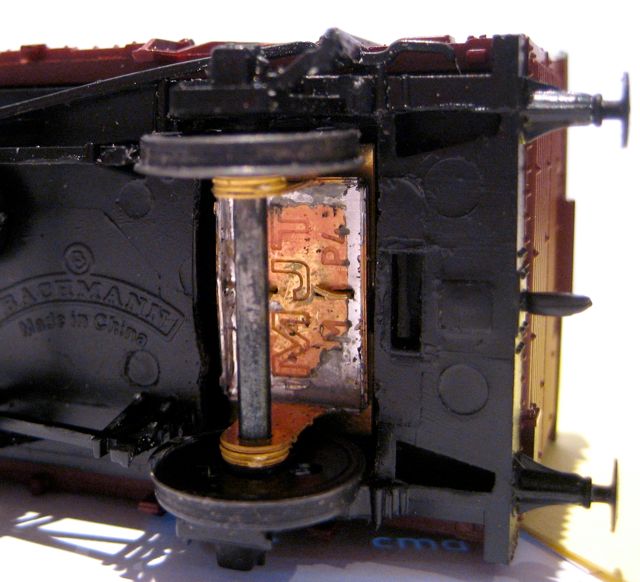

The day built up to assembling a compensation unit on a Bachmann wagon (mine to take away!):

and here is my first compensation unit (together with the first soldering for a model):

I am really pleased with this, and it has nicely overcome a hurdle in my progress to building a P4 layout - soldering up bits of brass for various things.

I'm so proud, I videoed it working over an obstacle, and it's here on YouTube:

We also tackled some track, which I think I'll post about separately.

Thanks are due to Terry and his assistants - it was great to be able to try things out and ask questions. Both soldering and track making will be things I look forward to doing more of. My fellow attendees made the day go well, and the MRC provided a great location and excellent tea

If you're tempted to attend something like this (perhaps at Scaleforum?), I would heartily recommend it. I will certainly be looking to attend more workshops like this in the future.

edit: Youtube tags